London-centered style company Bryden Wooden, with workplaces in Singapore, Barcelona, and Milan, will bolster its existence in the United States when it opens new headquarters in Boston this summertime.

Established in 1995, the firm now specializes in a benefit-oriented package-of-sections “Platform” technique to layout for manufacturing and assembly (DfMA). Bryden Wood’s North American enlargement is currently being led by directors Jaimie Johnstone and Phil Langley, its head of world techniques and creative technologies, respectively.

In an job interview with BD+C last 7 days, Johnston mentioned that Bryden Wood’s plans to increase into the U.S. in 2020 had been postponed because of the coronavirus pandemic. Prior to its transferring into Boston, Bryden Wooden had finished some get the job done in the U.S. for the pharmaceutical business GlaxoSmithKline. Amid the AEC and services-provider firms currently teaming with Bryden Wood on industrial assignments in the U.S. are The Boldt Business, Amazon Web Products and services, and DPR Design.

The timing of its expansion, claimed Johnston, was inspired by the sluggish-transferring speed in the U.K. toward adopting offsite manufacturing as an ingredient of business development. “There have been pockets of excellence, but also far more of a focus on volumetric modular for homebuilding.” The reverse is developing in the U.S., he observed, exactly where nonresidential developers and their AEC have been embracing prefabrication. Bryden Wood’s intention is to build a North American source community for industrial elements.

Johnston famous that whilst “a ton of people” in the U.S. are prefabricating MEP components, that aggressive edge “can be diluted more than time.” What Bryden Wooden delivers, he defined, is a merging of volumetric design with producing for much better and more quickly effects.

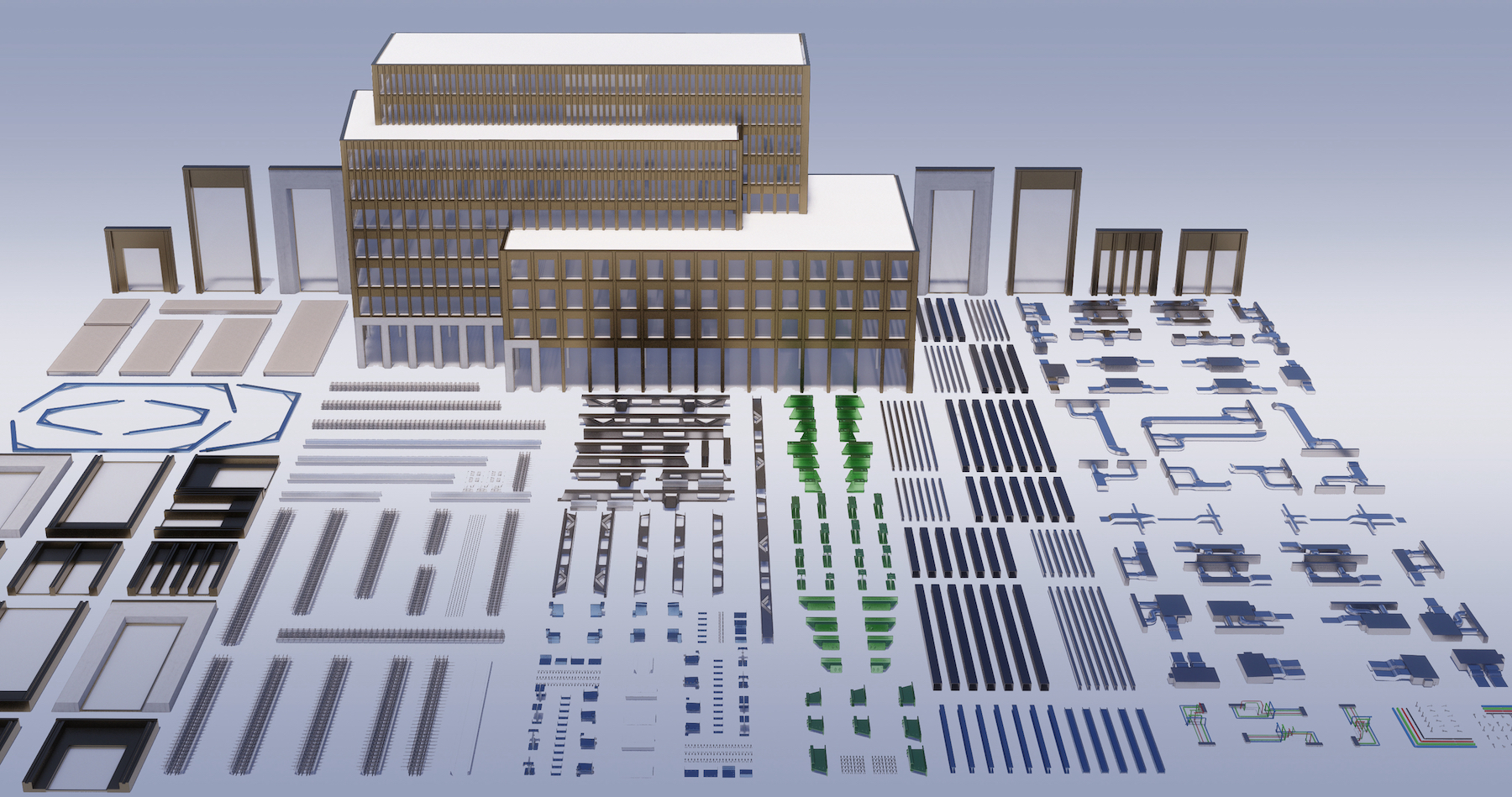

Bryden Wood’s Platform technique standardizes made elements that are made offsite and assembled onsite, thus assuring better certainty about schedules and budgets. Platforms also embed elements reuse and reductions in carbon into early phases of structure.

The company is effective with tech clientele to develop structure systems these kinds of as “digital configurators” that count on genetic algorithms to make countless numbers of design and style and engineering answers for sites close to the earth. By establishing methods that allow appropriate ranges of repeatability in this sort of developing sorts as info centers, without sacrificing high-quality, “we’re helping [clients] rework their firms,” said Johnston in a organized statement.

THE FORGE SHOWCASES Platform-Pushed Savings

The Forge has been a great deal more quickly and far more accurate.

The first major industrial job currently being delivered employing the Platform technique to DfMA is The Forge, which topped out previous December, and is scheduled for completion in the fourth quarter of this year. The Forge is comprised of two sustainably concentrated 9-story commercial buildings—90,000 and 49,000 sf, respectively—in central London, developed close to an accessible courtyard. Its projected efficiencies contain a nearly 20 p.c reduction in embodied carbon for each sq. meter, a 36.4 p.c reduction in the substructure, and a 20.2 reduction in superstructure and façade products. Johnston reported that the buildings’ façade panels could be put in in just 7½ minutes every, and with increased precision.

The Forge’s developer, Landsea, anticipates a 9.5 percent reduction in money fees from this platform package-of-pieces tactic. The Forge is also the U.K’s initial internet-zero vitality undertaking. The constructing workforce consists of a joint venture concerning the design companies Sir Robert McAlpine and Mace, and NG Bailey as the MEP engineer.

Johnston anticipated Bryden Wood to aim its notice in North American on tasks for healthcare, data centers, pharma, and industrial, “wherever there is a large degree of complexity and repetition.” On its web page, Bryden Wood claimed it has been developing knowledge facilities due to the fact 1999, and has been providing 30-40 p.c reductions in capital establish charges for every kilowatt, and an regular 40 per cent maximize in IT generate for every square meter.

Scalability via industrialized construction for these building styles is where by purchasers are most possible to advantage from advancements in style and design and supply, the agency contended. Johnston also foresaw Bryden Wooden carrying out a bit additional multifamily style in the U.S. than it does inside its dwelling marketplace.

A number of decades in the past, the firm launched a free-to-use and open-source housing structure application identified as PRiSM that, it promises, provides with each other central and regional federal government, investors, developers, and brands, with the goal of driving enhanced efficiency and top quality. The up-to-date model of PRiSM incorporates Bryden Wood’s Platforms strategy to DfMA.